scratch test lc1 lc2 lc3|Understanding of fracture conditions and material response in a : China © 2008-2024 ResearchGate GmbH. All rights reserved. Terms; Privacy; IP . Av João Jorge, 299 - Vila Industrial . Campinas, SP | 13035-680. Compartilhe . Mapa. Ativar mapa. Sugerir edições neste local. Outras empresas no ramo de Loterias em Campinas, SP. ULTRASORTE LOTERIAS. . LOTERICA DO TERMINAL. R Cônego Cipião - box-31 - Centro . Campinas, SP | CEP: 13010-010 . PONTO CHIC LOTERIAS. R Barão .

{plog:ftitle_list}

You are reading Jinx manga, one of the most popular manga covering in toons, Yaoi, Mature, Smut, Drama, Romance, Slice of life genres, written by Mingwa at MangaPuma, .

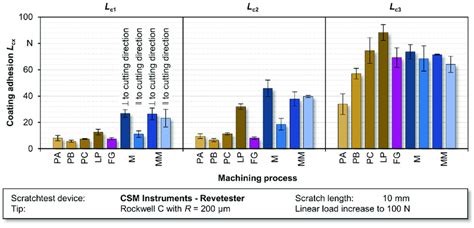

Download scientific diagram | Critical load values Lc1, Lc2, and Lc3 analyzed in a scratch test. from publication: Adapting the Surface Integrity of High-Speed Steel Tools for Sheet-Bulk.Download scientific diagram | Critical load values Lc1, Lc2, and Lc3 analyzed in a .© 2008-2024 ResearchGate GmbH. All rights reserved. Terms; Privacy; IP .

Lc1, Lc2, and Lc3 are well defined from an engineering perspective, and they are widely used to quantify the adhesive failures of film/substrate system. Lc1 indicates the .

Values of critical forces Lc1, Lc2, Lc3 in the scratch test.

For the DLC sample, the change in coefficient of friction and acoustic emission are great indicators for the first failure (Lc1), while confocal image provides better details for Lc2 .The Lc1 is generally considered as the appearance of the first cracks, the Lc2 as the first delamination or spallation, and the Lc3 as the full delamination. Examples of Lc1, Lc2 and Lc3 are illustrated on Figure 6a-c.The scratch test is a simple engineering test method used to assess adhesive bonding between coatings and substrates. This Guide aims to help you get the best out of your scratch tester. Although the scratch test is most often used for characterizing a top coating, there are also applications where it is a very useful technique for assessing the quality of a primer or .

Combination of high accuracy scratch tester and optical profilometer. Comprehensive analysis of deformation and failures during scratch. Finer view of surface and fracture during scratch. .Three scratch test failure events were identified for DLC (Fig. 1): forward chevron cracks at the borders of the scratch track (Lc1), forward chevron cracks at the borders of the scratch track accompanied by interfacial spallation (Lc2) and . The assessment of adhesion property of thin films by scratch test method is still a big challenge, relying on understanding accurately the material response and failure modes .

Download scientific diagram | Values of critical forces Lc1, Lc2, Lc3 in the scratch test. from publication: Corrosion and Wear-Resistant Composite Zirconium Nitride Layers Produced on.The purpose of a scratch test is to generate progressive damage to a coating. A diamond indenter is drawn . Lc1 Lc2 Lc3 Distance [m] Anton Paar Instruments Leveraging decades of experience, we’ve developed the broadest industrial portfolio of .The normal force at which the damage appears is referred to as a critical load (Lc). The main cases of changes and damage occurring during the scratch test can be classified as plastic deformation, cracking (Lc1), peeling (chipping) (Lc2), and penetration of the coating into the substrate in the central part of the scratch trace (Lc3).

The normal force at which the damage appears is referred to as a critical load (Lc). The main cases of changes and damage occurring during the scratch test can be classified as plastic deformation, cracking (Lc1), peeling . Scratch test results. Lc1 critical load is determined using the acoustic signals in scratch test data. However, the ability of getting acoustic signals is depended on the coating thickness. . Through thickness microcrack, buckling failure mode and buckle spallation failure mode are observed at critical loads Lc1, Lc2, and Lc3, respectively. 4.

简单的表述为,通过在显微镜下观察划痕的图像,标记出lc1和lc2甚至lc3的点,计算出现这些点的位置所施加的载荷大小。 通常LC1指划痕边缘开始出现裂纹,说明涂层开始失效,LC2指划痕开始出现剥落,说明涂层已经完全失效,一般我们用LC2来定义该涂层的结合力。TiNサンプルでは、アコースティックエミッションは最初の2つの障害(Lc1とLc2)を検出するための優れた信号を提供し、明視野での光学的観察はLc3に必要な検出を提供します。 . Lc1はサンプル間で有意差を示しませんが、Lc2とLc3はDLCサンプルよりもTiN .Three scratch test failure events were identified for DLC (Fig. 1): forward chevron cracks at the borders of the scratch track (Lc1), forward chevron cracks at the borders of the scratch track accompanied by interfacial spallation (Lc2) and gross interfacial shell-shaped spallation (Lc3).

(a) Optical critical loads Lc1, Lc2 and Lc3, derived from scratch testing. The coating significantly increases the critical loads. (b) Evolution of coefficient of friction during the tribology tests.For most clearcoats the change in Coefficient of fric- tion is a great indicator for the first 2 failures (Lc1 & Lc2) which is then confirmed with confocal images locating the first tears (Lc1) and the removal of the clearcoat (Lc2 & Lc3). Two paint panels were .

Acoustic emissions (AE) and friction forces were monitored online during scratch testing. The critical loads (Lc1, Lc2 and Lc3) that are used to define the failures of the film can then be determined combining the acoustic emissions curve and microscopy. Six scratches were performed on TiN film samples to obtain the average critical loads.RS-LC1/LC2/LC3. Application Liquid Level Control Relay is used for controlling liquid levels in wells and liquid tanks at industrial plants or agriculture irrigation. Data Sheet. Technical data. Power supply terminals. A1-A2. Rated supply voltage(Un) AC/DC 24 .

Download scientific diagram | Values of critical forces Lc1, Lc2, Lc3 in the scratch test. from publication: Corrosion and Wear-Resistant Composite Zirconium Nitride Layers Produced on the AZ91D .

The findings of scratch test showed that the calcined coating exhibited the ability to higher critical load. The relation between wear volume and dissipated cumulated energy was established for calcined and coated thin film, and the energetic wear coefficients of wear were deduced. . LC2, and LC3 in this study. LC1 indicates the failure .damage mechanism and failure modes under scratch loading. The test is performed by applying either a progressive (linearly increasing) or a constant load to create a scratch on the tested surface. Progressive load scratch tests have been extensively reported relating to coatings (Ref 26-31). Test results, such as the critical normal load (L1.1.1 Usual Procedure of the Scratch Test The scratch test consists of pressing a diamond stylus onto the surface of the coating, using either a constant or an increasing load, whilst moving the sample at a constant speed (Figure 1). The test at constant load may be a single-pass scratch test or a multiple-pass scratch test. Can someone explain the criteria used in determining whether a Parish falls within categories LC1, LC2, LC3 ,or LC4 for the purposes of deterring the Clerks remuneration. parish-council; asked Dec 3, 2020 by Grovebridge (120 points) answer. 2 Answers. 0 votes . There is an NALC and SLCC document that sets out the role descriptions for each .

Lc1、Lc2、およびLc3の例をFigure 6a-cに示します。 . Multi-Pass Scratch Test またはトライボロジーテスト試験片は、一定の亜臨界垂直力の下で、同じスクラッチトラック内で繰り返しスクラッチを受けます。 Progressive .在降解过程中,位于自噬溶酶体外膜的lc3-ii被半胱氨酸蛋白酶atg4b切割,产生lc3-i循环利用;位于内膜的lc3-ii则与包裹的内容物一起,被溶酶体降解。导致自噬溶酶体中lc3含量很低。 在自噬体形成时,胞浆型的lc3-i与pe结合并移动到自噬体的双层膜中形成膜型lc3-ii。 The three critical failure points are clearly visible but the limited depth-of-field is especially visible in Lc3 where only the bottom of the scratch track is in focus, whereas the rest of the image is a blur. . (Lc1) and first chipping (Lc2) events correspond directly to sudden jumps in the AE signal, whilst the tangential force signal .

Understanding of fracture conditions and material response in a

Quantitative description of the critical load in a scratch test still got considerable discrepancy between authors, the critical loads could be generally expressed by Lc1–3 [17], Lc1–4 . Lc1 and Lc2 decreased to 8.90 N with Lc3 of 15.60 N and Lc4 of 23.55 N. At 0.50 Pa and 0.70 Pa, the Cu thin films showed non obvious plastic deformation .It was adopted a displacement control numerical test and two load cases, respectively, one representing the real supports (LC1) and one other representing the applied displacement (LC2 . In general, three modes of degradation of hard deposits can be induced by the scratch test: cracking at a critical load called LC1, start of spalling at a critical load LC2 and total spalling at an LC3 critical load. 3.3 Tribological Properties. The tribological behavior was studied using continuously loaded single scratches and multi-scratches.Table 3. Experimental data derived from the scratch test with the corresponding values of the critical load (LC1, LC2 and LC3) for the DLC WC:C coating sample. TEST LC1 LC2 LC3 Data 1 Data 2 Data 3 Data 4 Average 12 N 10 N 10 N 9N 10.5 ± 1.5 N 27 N 29 N 28 N 26 N 27.5 ± 1.5 N 48 N 52 N 51 N 45 N 48.5 ± 3.5 N 3.1.4.

LC3 is a new blend of two materials which have a synergetic effect. can reduce half of the clinker content and therby cut up to 40% of the CO2-emissions. Furthermore, LC3 uses industrial waste materials which thereby increase the resource efficiency and reduce the utilization of the scarce raw materials that are necessary for producing clinker. . In the test process , an Al 2 O 3 . (LC1, LC2, and LC3) in scratch testing of titanium alloy samples with Cr-Al-Si-N, DLC-Si, and Cr-Al-Si-N/DLC-Si coatings. The lowest adhesive bond strength among the studied coatings is observed in samples with DLC-Si coatings (the first signs of cohesive destruction are observed at the LC1 of less than 3 .

The LC2 and LC3 Collections (1928), referred to by its creators as “cushion baskets,” are a modernist response to traditional club chairs. Its most iconic feature is the reversal of a traditional sofa structure, which put the metal supports outside the cushions.

The adhesion strength measured by scratch testing of sol-gel fluorinated hydroxyapatite (HA) coating applied in Ti 6 Al 4 V titanium alloy has shown marked improvement with an increase in firing temperature (Zhang et al., 2006).While the average adhesion strength of a nonfluorinated HA coating cured at 500°C was found to be 0.37 N which rose to 0.47 N when cured at 700°C, .

Intelligent Tensile Tester broker

The current state

WEBAgregando pra JÁ!! Preciso de Entregadores com Carro filmado e disponibilidade de carregar todos os dias de manhã 06:00 Ceps: 080 - São Miguel Paulista 081 - Itaim Paulista Base na Vila.

scratch test lc1 lc2 lc3|Understanding of fracture conditions and material response in a